Ref. REDS MRO:PC214-00389

Previous.ref : PC214-00389

Ref.maker : I-633C5

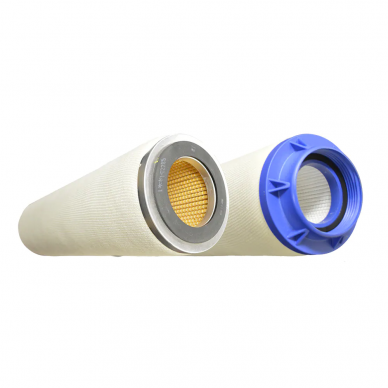

Coalescing cartridges are used as the first stage in filtration/separation tanks for hydrocarbon fluids. They perform two functions: (1) coalesce (combine) emulsified and highly dispersed water particles into larger water droplets and (2) filter particulate contaminants.

Cost-effective removal of particles and emulsified water from hydrocarbon fluids

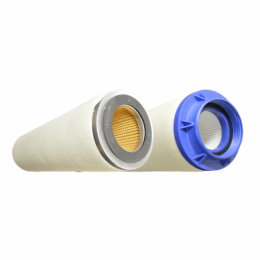

Easy installation and replacement thanks to one-piece design.

Choice of threaded base or open end cartridges.

Choice of all-fibreglass media or a combination of fibreglass and pleated media.

Field-proven performance

Continuous qualification testing to meet evolving commercial and military requirements.

Used as a first stage cartridge in filter/separators.

Removes particles and coalesces water into large droplets.

Also available with screw base

Model number system. See box on right. The one or two-digit series designation corresponds to the approximate number of microns of each coalescing cartridge model. Note that this is a nominal value and should be used for reference only.

The ‘0’, ‘2’ and ‘4’ series fibreglass cartridges have a nominal capacity of 25, 5 and 3 microns respectively. The ‘2’ and ‘4’ series are commonly used with diesel and other fuels, and represent a compromise between filtration efficiency (cartridge life) and water removal capacity. They coalesce raw water, but do not normally remove fine water particles.

The all-fibreglass ‘6’ series was originally developed for jet fuel (original specification MIL-F-8901). With an index of 2 microns, it has proven to be the most cost-effective design in some jet fuel applications. The ‘6’ series cartridges are also used in the petrol filtration service. However, it should be noted that the powerful detergent additives contained in most automotive gasolines reduce the coalescing ability of this and other designs.

83’ series cartridges. The ‘83’ series cartridges, with a capacity of 1 micron, are fibreglass and pleated media cartridges. The highly practical ‘83’ series cartridges have become the most widely used model in applications such as petrol, condensate and insulating oil filtration.

85’ and “87” series cartridges. The ‘85’ series has a 0.5 micron capacity, while the ‘87’ series has a 0.3 micron capacity. Both incorporate multi-layer pleated media. The ‘85’ series has consistently demonstrated superior dirt-holding capacity in the field.

JF5 series coalescers. The JF5 cartridges are Velcon's latest design. Combined with the V5N5 series separators, they offer higher flow rates and longer service life. See data sheet #1923 for more information.

General specifications

Maximum differential pressure of 75 psi

pH range from 5 to 9

Maximum operating temperature 150°-160°F

Aluminium centre tube

Buna-N seals

Injection-moulded end caps are standard on coalescers with a 6’ diameter threaded base;

Aluminium end caps are standard on 6’ diameter open end cartridges.

All end caps on 6’ diameter cartridges are bonded directly to the media with epoxy or high-strength urethane.

The 4’ diameter cartridges have end caps moulded in polyester resin or injection moulded.

Technical specifications

Certifications: Category M, MIL-PRF-52308J

Outer casing: N/A

Seal material : Buna-N

Micron rating (µm):0.4

Filter construction: glass fibre

Application: Military Aviation

End cap configuration: open end

Inside diameter (inches):1.19

Outside diameter (inches):3.75

Length (inches):20.125

Filter type: coalescer

Maximum operating temperature: 66-71°C, 150-160°F

Maximum differential pressure: 5.2 bar (75 psi)

Changeover pressure differential: 15 psi, 1 bar

pH range: Continuous operation: 5 - 9

Make: Velcon.